The modern production process virtually doesn’t exist without robotics and automation. This isn’t merely the peak of current technological thinking, as successive “revolutions” (such as Industry 4.0) continually impose specific trends—such as even tighter communication between the various elements of this complex puzzle. How can such different devices be integrated? Naturally, with the help of a modular edge gateway.

The ongoing industrial revolution 4.0

The mentioned robotics and automation of industrial production seem to have only benefits. Indeed, they bring huge advantages in terms of process scalability, repeatability, and thus the ability to maintain consistent quality of the final product. The Fourth Industrial Revolution, or simply “Industry 4.0,” which we are witnessing, goes a step further by focusing on full integration and digitization, including via IoT, cloud computing, and AI. This enables real-time monitoring and analytics of virtually every parameter—of machines, devices, their surroundings, and the materials being processed.

All this data must be aggregated, processed, and delivered to the end user through a dedicated infrastructure—which, regardless of its topology or application, must be reliable in terms of performance, connection stability, and security.

Industrial infrastructure with KLAS edge gateway

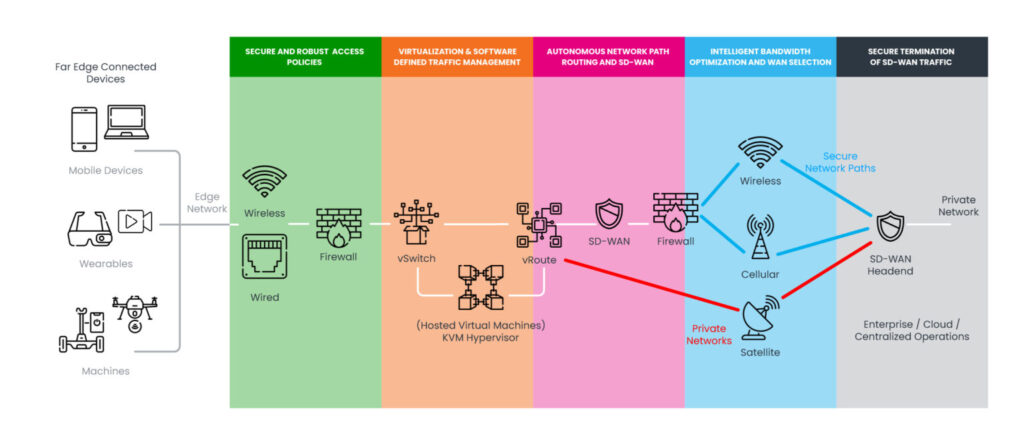

This is where KLAS technology comes into play. Thanks to its mobility, resilience, and flexibility, it fits perfectly into the needs of modern industrial plants.

Distributed production environments, real-time monitoring systems, and integration of data from thousands of IoT sensors—all of these require edge gateways that can operate with military-grade reliability, while meeting industrial standards (resistance to extreme temperatures, potential mechanical damage). KLAS TRX modules and Voyager mobile systems enable data processing and transmission at the network edge (edge computing), significantly improving the efficiency, security, and operational resilience of industrial facilities.

source: https://www.klasgroup.com/keel/

KLAS hardware can function as: an independent network node in hard-to-reach areas of the plant, a mobile data center supporting production, or a secure access and monitoring point for IoT installations, SCADA systems, or autonomous robots. It supports protocols such as MQTT, HTTP, Modbus RTU, LoRaWAN, and also enables the creation of encrypted VPN tunnels using SD-WAN.

Top 4 IoT protocols used in industry and their real applications

Since the idea of Industry 4.0 is the integration of diverse devices capturing different parameters, it’s worth taking a look at which protocols are most commonly used in practice and how they communicate. Note: the following list is subjective.

MQTT (Message Queuing Telemetry Transport)

A lightweight network communication protocol over TCP, based on a publish/subscribe pattern through communication channels via a broker. The main advantage is its low energy and bandwidth consumption.

Practical examples: IoT sensors for temperature, humidity, noise, and lighting.

Integration with KLAS:

- Reception technology: Wi-Fi / LTE / Ethernet

- Implementation: TRX as MQTT broker or client, processes data locally via KlasOS Keel (Edge Computing)

- Application: Local storage, analysis, forwarding to headquarters via SD-WAN/VPN

Modbus RTU, TCP, ASCII

A client-server protocol used for character-based information exchange between devices in industrial automation systems. It is available via serial transmission and TCP/IP on port 502.

Examples include: electricity meters, differential pressure sensors, and temperature/humidity sensors.

Integration with KLAS:

- Reception technology: Modbus TCP – directly via Ethernet / LTE VPN

- Implementation: TRX with KlasOS as master/slave or data logger

- Application: local processing, anomaly detection, data transfer to the cloud

CAN (Controller Area Network)

A fast, interference-resistant serial bus protocol created for real-time communication between electronic devices. Originally developed for the automotive industry, today it is widely used in Industry 4.0, automation, and robotics.

Examples: acceleration and tilt sensors, engine pressure sensors

Integration with KLAS:

- Reception technology: CAN port with a CAN–Ethernet adapter or via a gateway converting CAN to IP

- Implementation: TRX with Ethernet + local processing + lokalne przetwarzanie

- Application: real-time parameter logging, e.g., in vehicles (Jump Server)

RTSP (Real-Time Streaming Protocol)

An application-level protocol used for controlling audio and video streaming in real time. It allows clients to control playback (play, pause, stop, seek) of media streamed from a media server.

It is primarily used in surveillance systems and thermal imaging.

Integration with KLAS:

- Reception technology: Ethernet or Wi-Fi, RTSP transmission

- Implementation: TRX as a recorder or stream relay (e.g., to headquarters via VPN/SD-WAN)

- Application: local video recording or edge stream analysis

Comments are closed